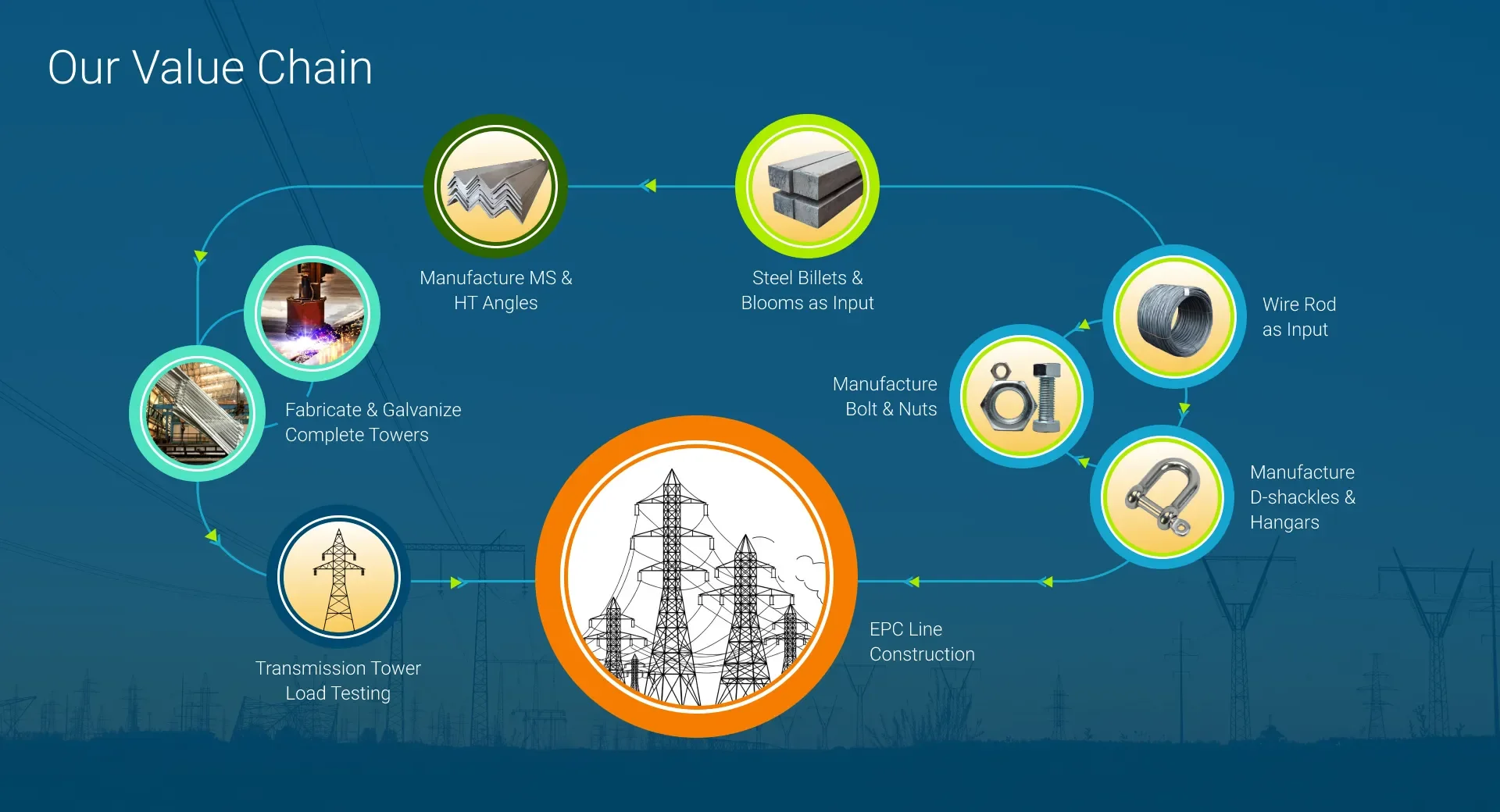

Trusted partner for power transmission infrastructure

Skipper Limited is one of the largest tower manufacturers globally, exporting to over 65+ countries. Our commitment to quality and engineering excellence has earned us a trusted partnership with Ramboll, the global leader in tower design.

As an ISO 9001-certified company, Skipper Limited ensures the highest standards across all stages of tower production. We operate one of the world’s largest Tower & Monopole Testing Stations, capable of testing all types of lattice and guyed towers to world-class technical specifications.

From designing and manufacturing to custom prototyping, Skipper Limited handles every step of the process, delivering reliable solutions for power transmission projects in North America.

Product specifications

Skipper Limited’s Lattice Towers are engineered to meet the most demanding high-voltage requirements across North America, supporting up to 765 kV. They are manufactured from high-grade steel rolled to ASTM A572, with hardware produced to international quality standards. All components are galvanized in-house, providing long-lasting corrosion protection. Built for versatility, these towers perform reliably across diverse terrains, from urban corridors to remote regions. Each tower undergoes prototype assembly and load testing to ensure proper fit, structural integrity, and performance.

World-Class Manufacturing Capability

Skipper Limited is ranked among the top 10 largest utility structure manufacturers globally.

Key strengths of Skipper’s Lattice Towers

Comprehensive product range

Skipper Limited offers a diverse product portfolio, with custom solutions ranging from 66 kV to 800 kV towers to meet the needs of North America’s power transmission projects.

100% Material traceability

We ensure 100% traceability from billets to finished towers, using only fully tested billets from major steel plants.

Strong quality assurance and modern testing facilities

Skipper Limited operates ISO-certified in-house testing labs, ensuring rigorous quality control at every stage.

Optimized design and engineering

Our in-house design and engineering department ensures precise structure fitment and optimal design, eliminating the need for site rectifications and installation delays.

On-time delivery

Skipper guarantees on-time delivery, with project timelines ranging from 17 to 28 weeks ARO. We prioritize efficiency and reliability, ensuring that your infrastructure projects stay on schedule.

High-Volume Galvanizing

Seven In-House Galvanizing Plants with a capacity exceeding 300,000 MT per year, ensuring superior hot-dip galvanizing for corrosion resistance.