Since its inception, Skipper has consistently invested in Research & Development to foster innovation and excellence. Our Dedicated R&D Centre in Howrah, West Bengal, is recognized by the Department of Scientific & Industrial Research (DSIR), Ministry of Science & Technology, Government of India. Backed by Strong R&D Infrastructure and Expertise, Skipper has pioneered several first-of-its-kind products in India, reinforcing its position as an industry innovator. Through continuous R&D efforts, the company continues to strengthen its leadership in the transmission and distribution sector.

Looking ahead, Skipper is expanding its R&D initiatives not only to enhance its existing portfolio but also to diversify into new products and services. Our primary objective is to remain future-ready and a pioneer in technology, creating sustainable value for our customers and stakeholders.

Comprehensive Testing Capabilities

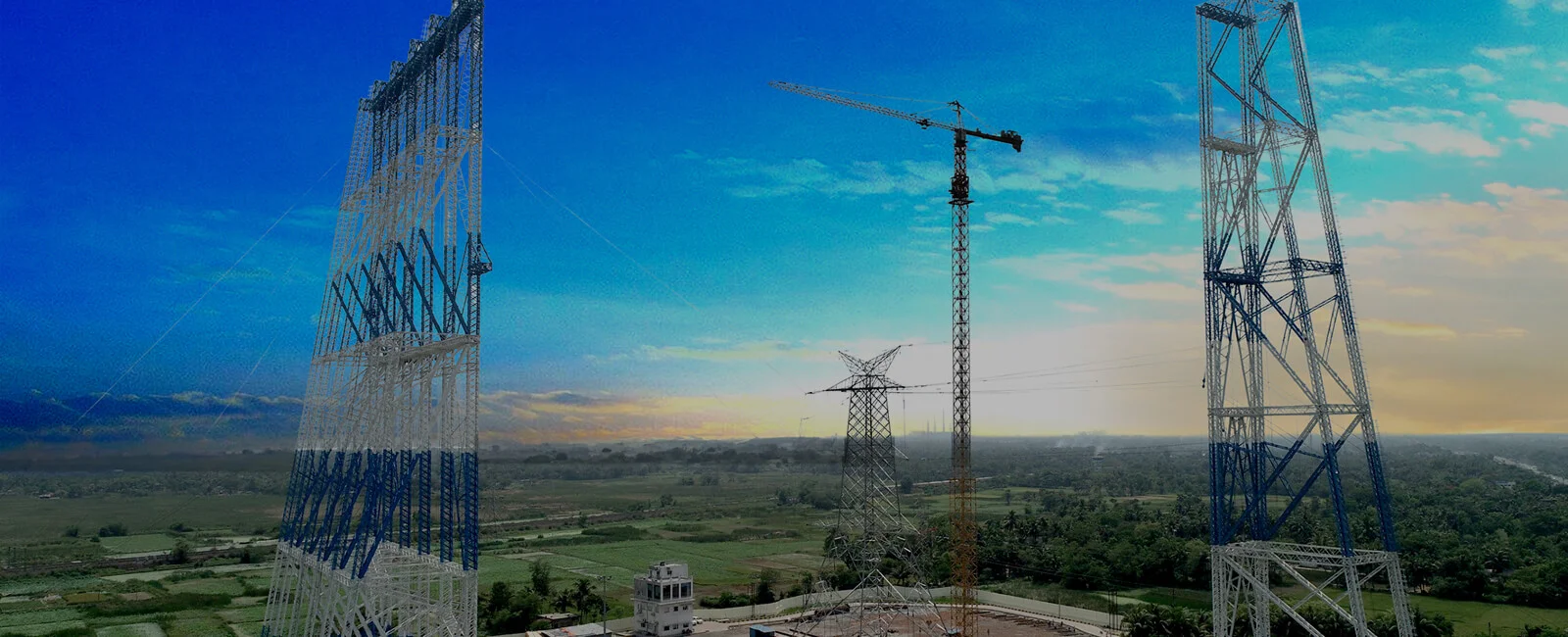

Our Full-Scale Prototype Test Station is equipped with cutting-edge technology to perform. In 2020, Skipper further strengthened its innovation ecosystem by commissioning one of the World’s Largest Tower Testing Stations to support advanced R&D activities. The Testing Station is equipped with State-of-the-art infrastructure to test all types of transmission towers and poles.

Self-Supported Lattice Tower

Most widely used for its modularity, durability, and ease of installation.

Monopoles

Smaller footprint, Aesthetic, Best Suited for City Centres/Highways.

Substation Structures

Integral part of the transmission system.

Why Choose Skipper for Transmission EPC?

Two Fully Independent Transmission Tower Test Beds at One Location

A unique dual setup enables simultaneous testing, faster project turnaround, and unmatched efficiency. Customers can witness two tests in a single visit.

Dedicated Prototype Manufacturing Plant

Supports seamless testing operations, ensuring timely fabrication and delivery of tower components.

Robust Backward Integration

A dedicated in-house rolling mill gives Skipper complete control over raw material availability, ensuring efficiency, reliability, and optimal delivery timelines.

24×7 Operations

Operating round the clock, Skipper is the only testing station globally with continuous year-round operations, ensuring faster turnaround and enhanced testing efficiency.

Globally Accredited Excellence

Skipper holds ISO/IEC 17025:2017 accreditation, ensuring globally recognized standards of measurement accuracy, operational safety, and testing reliability.